Tornos company, by producing and supplying all kinds of machine models, especially CNC Deco Tornos, has long been welcomed as a famous brand by different people who are always looking for standard products.

Expert engineers work in the design and manufacture of this group of machines, whose policy is to provide quality with the best materials, it is not without reason that they have gained a valuable position compared to other competitors. The ability of experts and special manufacturing technology of the company is tangible with the production and supply of Swiss-type automatic lathes and multi-spindle machines. It is not without reason that it is also known as the main arm of this industry.

The beginning of the activity of this famous company dates back to 1880, when a serious evolution was presented in the presentation of Swiss-type lathe technology. Flipping through the brilliant record of a hundred years of activity can show the quality and countless benefits in such a way that in addition to the resistance and reasonable lifespan of the products, the focus has always been on providing innovation and providing quality products.

The unique efficiency and reasonable appearance of the products has made it to leave a brilliant record in various fields such as automobile manufacturing, medicine, dentistry, micromechanics and electronics.

Active agencies were established in the corners of the world and in more than 80 countries to provide outstanding services in the shortest possible time. Not only do they explain the terms and conditions, but experts who are skilled in deciphering the problems also follow the troubleshooting process with written programs. Customers can experience easy, convenient and hassle-free access, in addition to eliminating the opportunity for profiteers who offer low-quality and copycat products at exorbitant prices.

The cost of the products is reasonable, so that the products of this brand are known as an economic option, which, by providing great options and facilities, were able to overcome the competitors of the same category and different customers from services such as buying machines, turnkey projects, repair services. And machine maintenance and learning in the troubleshooting area will also benefit.

History of the Swiss type device

The 1960s can be considered a turning point in industrial activity, which was not unrelated to the production of Swiss-type devices. The production and supply of CNC machines in 1970 was able to meet the needs of customers, which was also considered as a smart choice, but after some time, the optimization process of such machines was considered, which should be based on the slide movement. took

The reception and popularity of different classes led to the investment and provision of fixed and mobile tools, including equipping milling machines and spindles with independent machining tools. The production and presentation of Swiss-type devices in 1980 was able to make the electronics industry astounded by the design and manufacturing capabilities of this brand.

The advancement of technology and offering flagship products does not end here, in 1990, expert designers were able to improve the controls and servo motors, making powerful support possible in such a way that CNC machines, more advanced and faster, could overcome the limits of the industries. it is not without reason that aerospace industries, medical services and dental industry were able to benefit from these cost-effective products.

It should not be forgotten that the brilliant performance of this brand in the production and presentation of Deko Tornos machines has led to reasonable optimization in such a way that they gained a better position than normal machining operations.

Specifications of SwissDECO devices

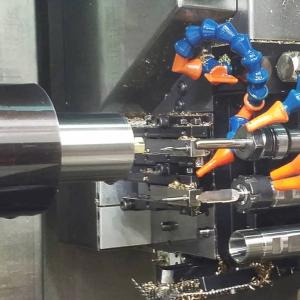

SwissDECO can be seen as a mirror of the expertise and skill of Tornos specialists, who are always improving production standards. One of the key features of these products is the presence of an independent tool system with a diameter of 36 mm.

Choosing Deko machines can be a safe purchase that, in addition to being an economical and user-friendly option with unique flexibility, allows the opportunity of various operations. The specialists of this brand are equipped with a basic roadmap to provide standard services in addition to the brilliant history of their activities so that all classes can buy original and quality products.

The activity history of Deko Tournos collection has been nearly a century, and by offering flagship products, it always adheres to the production standards. It is not without reason that, in addition to gaining the trust of various users, it has also been able to display the professional skills of its specialists. Many describe the company's products as a true vision of the future of bar turning.

These items are not the only features of this brand's manufacturing index, a compartment is referred to as part of the basic equipment in which engineers embed different tools that help to implement index operations that can be expected to operate independently.

Different users in industries mentioned the installation of different equipment such as a chip conveyor, a heat exchanger, a paper filter device, different versions of a high pressure pump and in some cases a filter device. The existence of a variety of models for different strata has made it easier to choose the desired specifications.

Getting to know the different models of the CNC Deco Tornos machine

One of the prominent features of the Deko Tornos G model with a double screen can be mentioned the installation of 9 linear axes.

For convenience and effective follow-up of roughing, finishing, deep drilling operations, as well as working in differential mode, the expert designers also made the Z axis on the second page, the significant advancement of technology can be seen in this device, which is actually with three The independent instrument system has a dual screen.

The expert managers and engineers of this collection include modular devices and pre-set tool systems as default